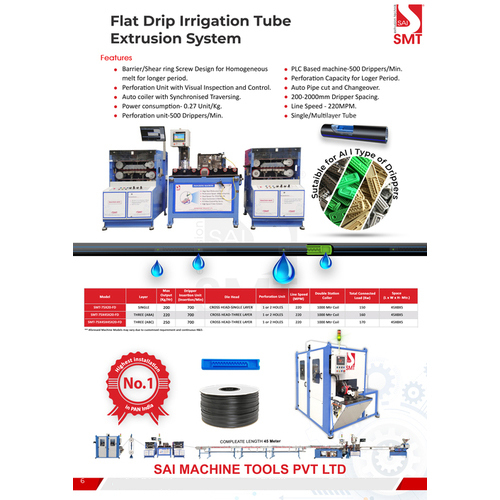

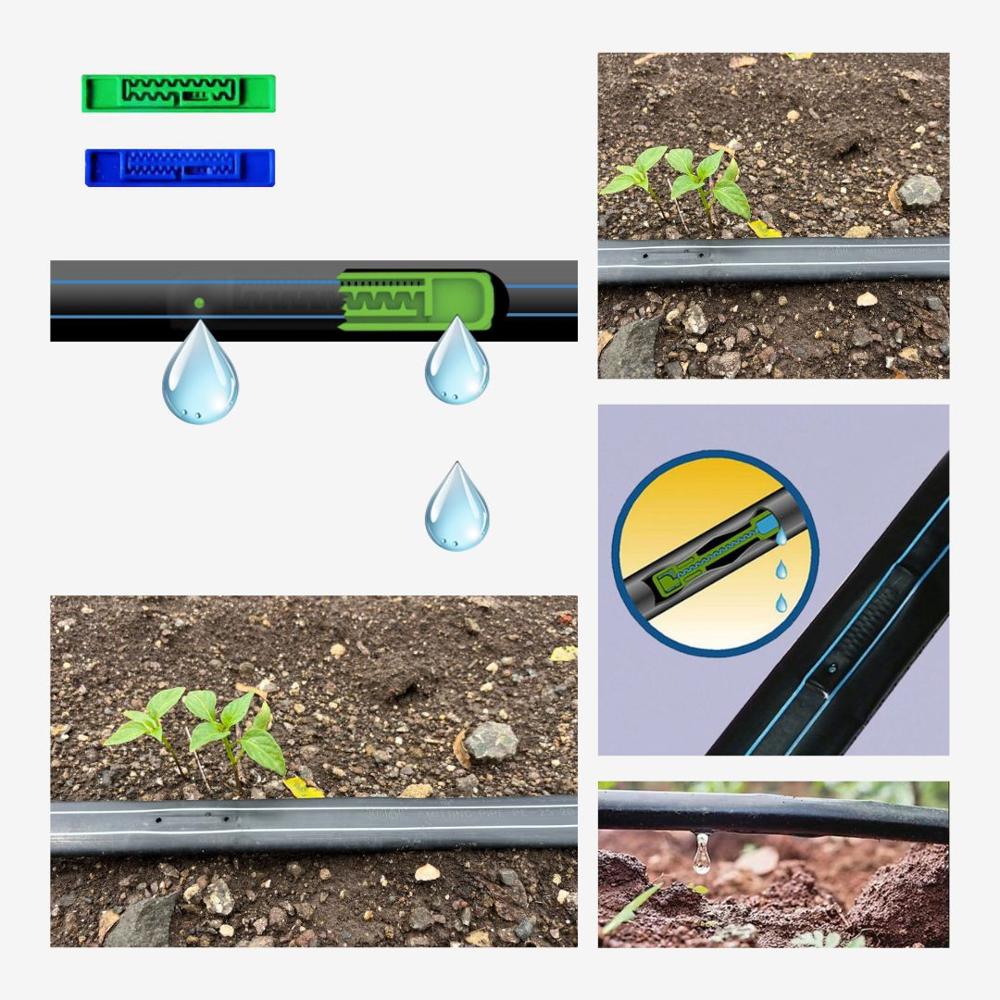

Drip Irrigation Pipe plant for (Flat Drip Type)

Product Details:

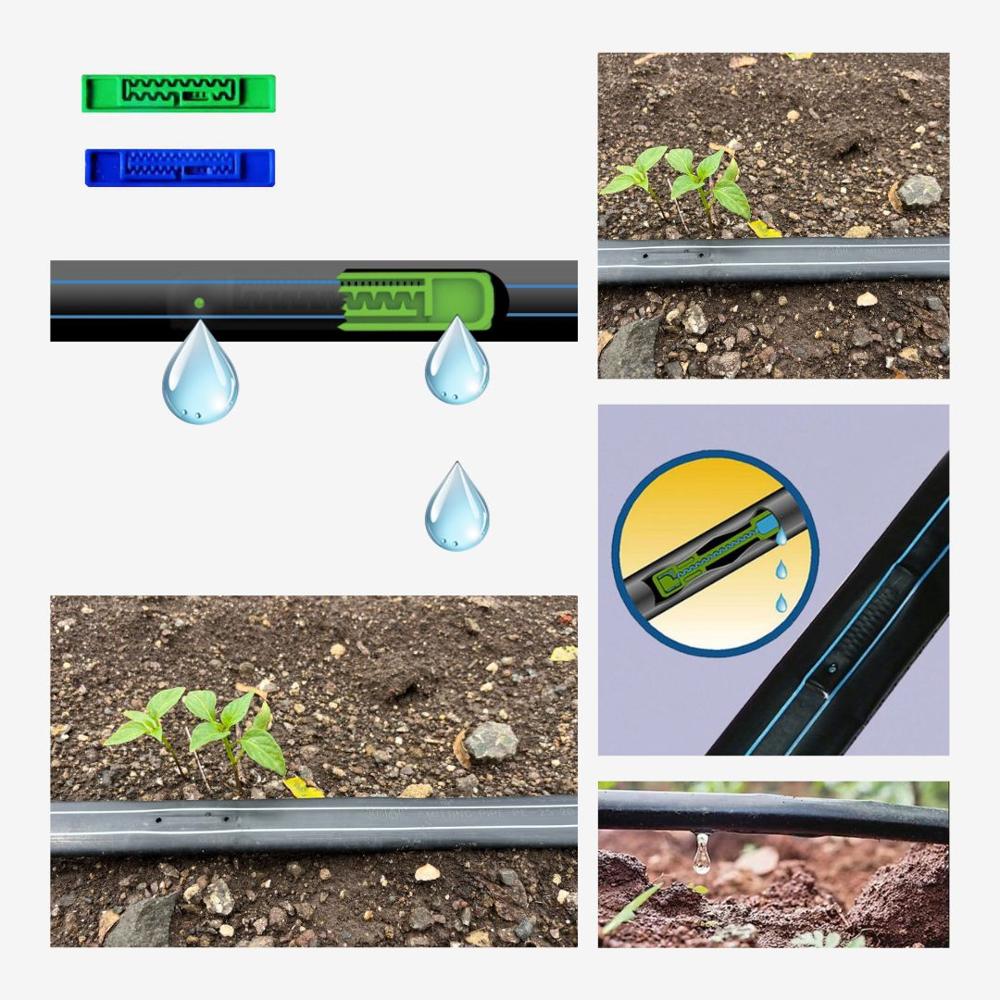

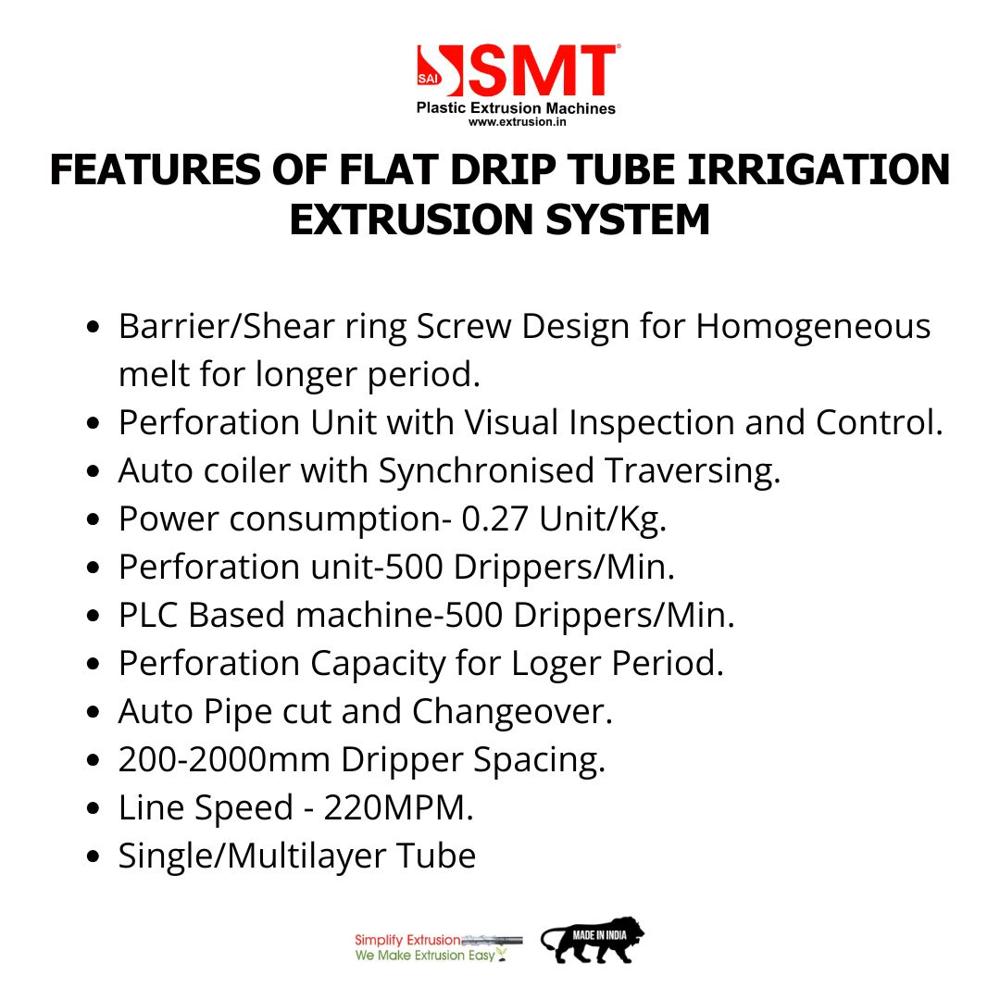

- Usage & Applications 1. Manufacturing of Flat Drip Irrigation Pipes, 2. Suitable for agriculture & irrigation industries. 3. Ideal for water-saving irrigation projects. 4. Widely used by pipe manufacturers and OEMs

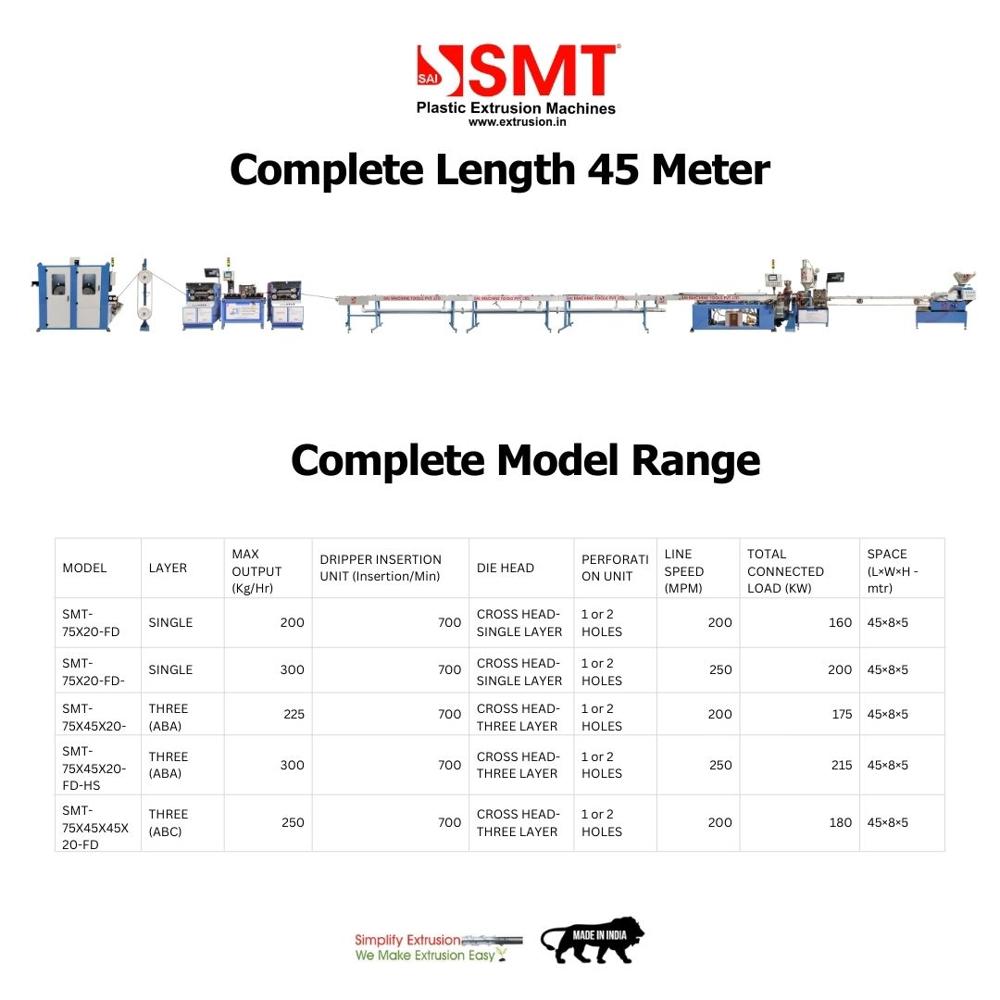

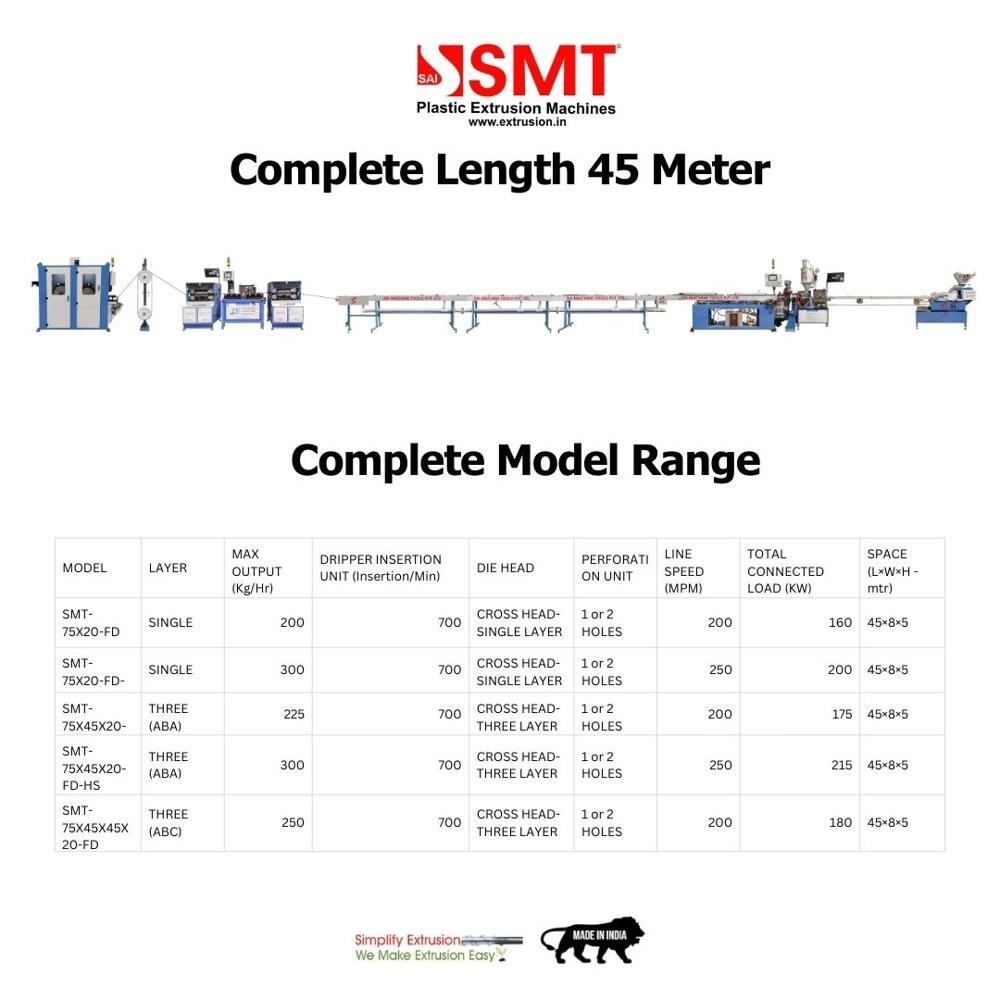

- Speed 220 m/m

- Motor Power 300 Kilowatt (kW)

- Type Pipe Extrusion Line

- Material LLDPE & HDPE

- Computerized Yes

- Automatic Grade Automatic

- Click to View more

Drip Irrigation Pipe plant for (Flat Drip Type) Price And Quantity

- 9500000.0 INR/Kilograms

- 1 Piece

Drip Irrigation Pipe plant for (Flat Drip Type) Product Specifications

- 300 Kilowatt (kW)

- Electric

- Blue and White

- Yes

- Automatic

- 1 year

- Pipe Extrusion Line

- 220 m/m

- 300 Kg/hr

- 300 Kilowatt (kW)

- 100 Watt (w)

- LLDPE & HDPE

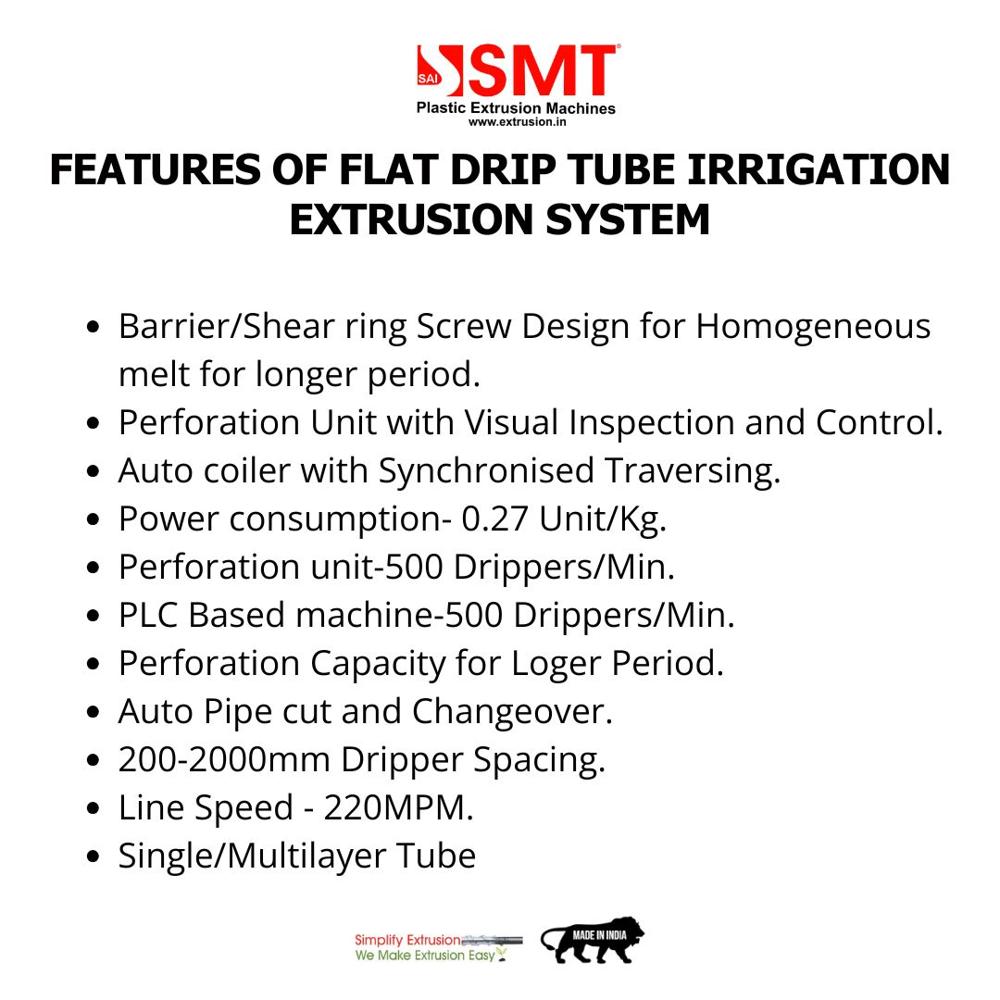

- 1. High Speed & Productivity. 2. Line speed up to 220 meters per minute. 3. Insertion & perforation capacity of 700 drippers per minute. 4.0 Supports dripper spacing from 200 mm to 2000 mm

- PLC Control

- 180 Watt (w)

- 1. Manufacturing of Flat Drip Irrigation Pipes, 2. Suitable for agriculture & irrigation industries. 3. Ideal for water-saving irrigation projects. 4. Widely used by pipe manufacturers and OEMs

Drip Irrigation Pipe plant for (Flat Drip Type) Trade Information

- 15 Piece Per Week

- 1 Week

- All India

Product Description

With over 37 years of experience in the plastic processing industry, Sai Machine Tools Pvt. Ltd. has established itself as a leading and reliable manufacturer of high-performance PVC Compounding Mixer Machines. Since 1988, we have been delivering advanced mixing solutions trusted by manufacturers across India and global markets.

Our PVC Compounding Mixer is designed for efficient and uniform mixing of thermoplastic materials such as PVC, PE, PP, ABS, and other plastic resins. Built with deep industry knowledge and engineering precision, this machine is essential for processes likeplastic extrusion, masterbatch compounding, cable insulation mixing, andWPC (Wood-Plastic Composite) preparation.

The mixer unit consists of two integrated components:

1. A Hot Mixer, where the raw materials are rapidly blended and heated to the desired temperature.

2. ACooling Mixer, where the heated mixture is immediately cooled to stabilize the compound and prevent thermal degradation.

This two-stage process ensures:

-

Consistent material quality

-

Uniform color dispersion

-

Improved thermal and mechanical properties of the final compound

By combining proven engineering with real-world manufacturing expertise, Sai Machine Tools delivers a mixer solution that enhances productivity, reduces batch variation, and ensures superior output for every application.

Product Highlights:

-

Efficient Mixing:Achieve faster blending and high-speed dispersion of resins and additives.

-

Energy Efficient:Designed with precision motors for reduced power consumption.

-

Durable Construction:Built using high-grade SS304 stainless steel.

-

Safe & User-Friendly:Features automatic temperature control, overload protection, and optional PLC control.

-

Versatile Applications:Ideal for PVC Pipe Plants, Masterbatch Mixing, Granule Coloring, Cable Compounds, etc.

Technical Specifications:

|

Parameter |

Details |

|

Type |

High-Speed Vertical Mixer Unit |

|

Mixing System |

Hot Mixer + Cooling Mixer |

|

Capacity |

100/300 L, 200/500 L, 300/1000 L |

|

Motor Power |

20 HP to 75 HP |

|

Material of Contact |

SS304 Stainless Steel |

|

Speed |

650 1500 RPM |

|

Control System |

Manual / Digital PLC |

|

Output |

Uniform mixing of plastic compounds |

Why Choose Us?

-

Over37+ years of industry experience

-

Supplied to 35+ countries worldwide

-

Backed by ISO-certified processes

-

Strongafter-sales serviceandspare parts support

-

Thousands of successful installations in India & abroad

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Inline Dripper Irrigation Tube Extrusion Line' category

|

SAI MACHINE TOOLS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese