Welcome to Sai Machine Tools Pvt. Ltd.

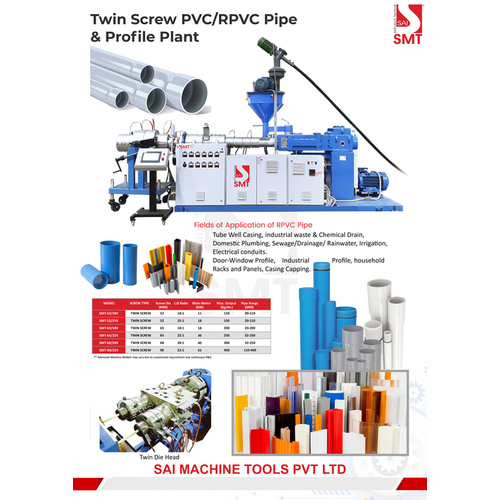

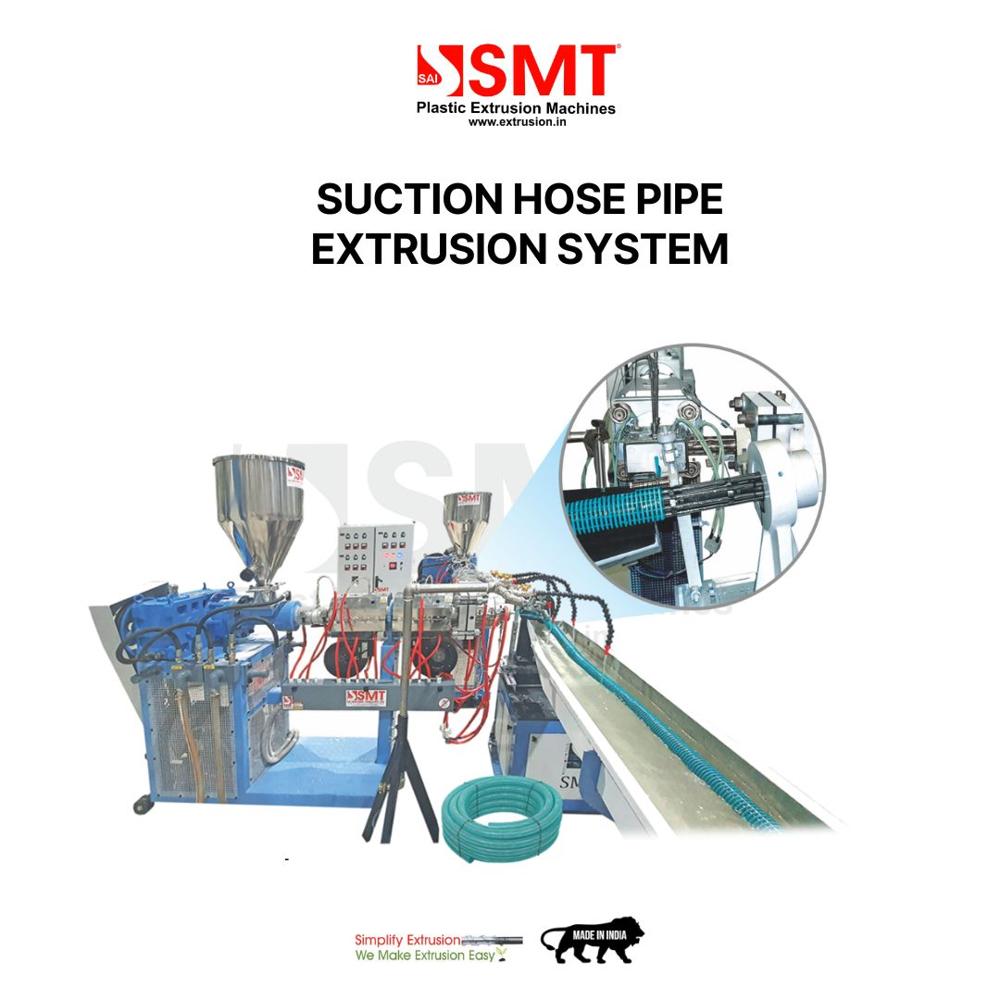

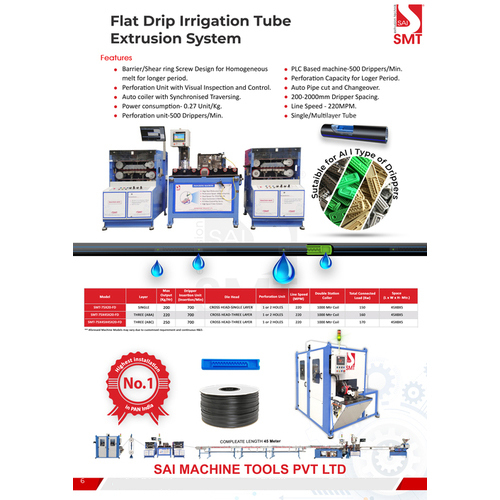

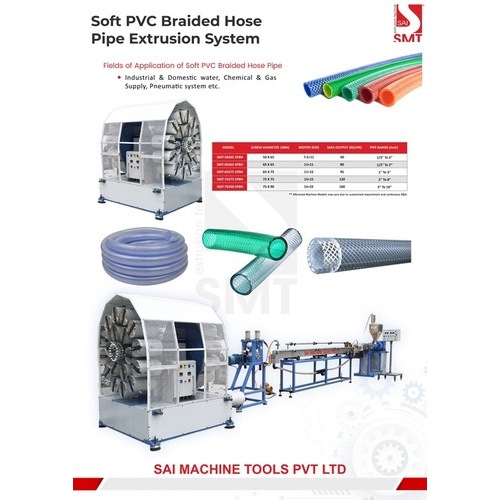

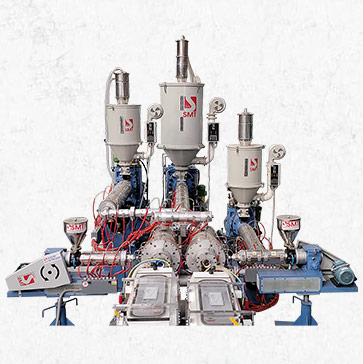

We are dealing in Drip Irrigation Machine, Drip Irrigation Pipe Machine, Single Screw Extruder, Twin Screw Extruder, Post Extrusion Equipments, PP Blown Film Plant, PVC Blown Film Plant etc...

Quality

Sai Machine Tools Pvt. Ltd. is equipped with the latest machines like Less Brander Thread Milling Screw Cutting Machines, Single Screw ExtruderClients

As a customer-oriented company, Sai Machine Tools Pvt. Ltd. adheres to its core values and aspires to always remain as the preferred vendor

About Sai Machine Tools Pvt. Ltd.

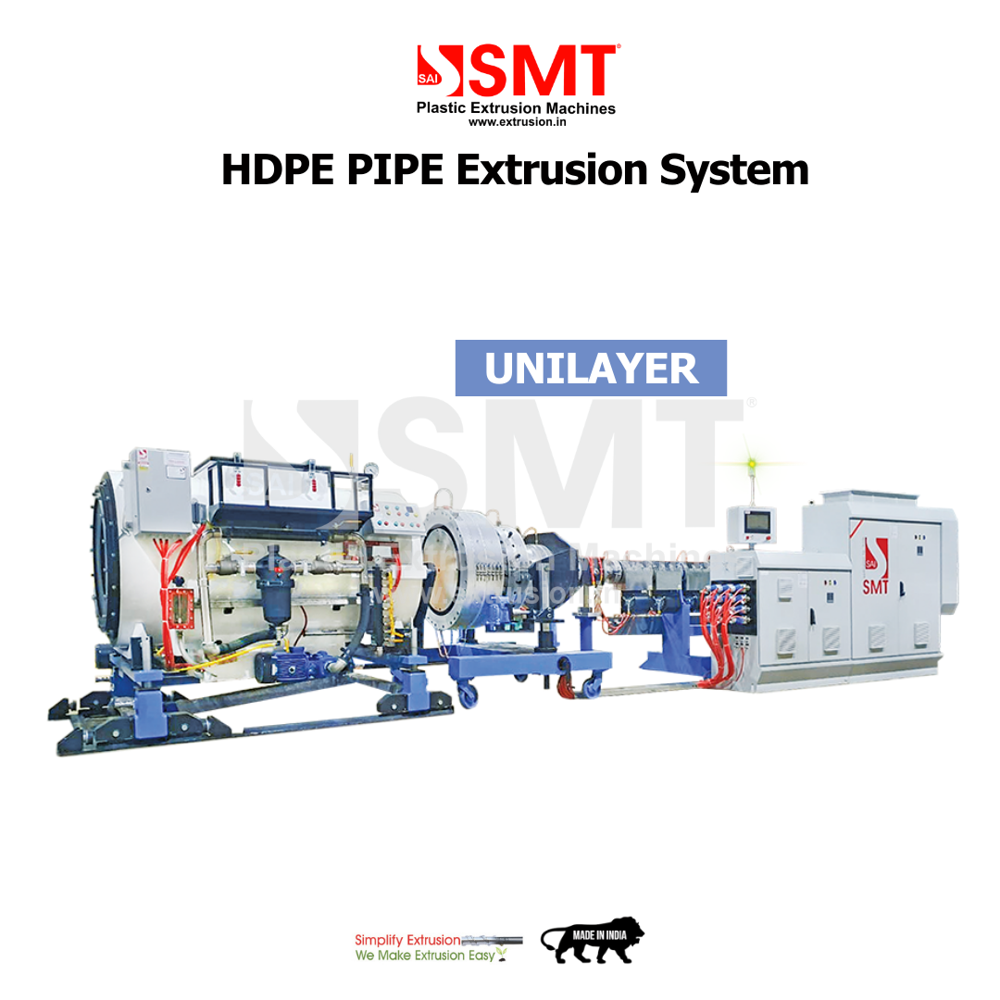

Since the launch of the company in the year 1988, Sai Machine Tools Pvt. Ltd. has functioned with a vision of allowing its products to be availed by a cross section of industries. We are a leading Manufacturer, Exporter, Wholesaler/Distributor, Supplier & Trader of Plastic Processing Machines (Extruders) for the production of RPVC Pipes and Profiles, HDPE, LLDPE, HMHDPE Pipes and Films, PVC Coated Cables, Telephone Cables, Computer Cables and Pelletizing Plants, Mono Filament, Box Strapping Plants, PP/PE Tape Plants, Drip Irrigation Round & Flat Tube Extrusion Plant, PP Blown Film Plant, PVC Blown Film Plant etc.

Our sales volume has reached INR 25 crore, due to the diverse market penetration and the mass products distribution. We have been accredited with ISO 9000:2001 certification for our outstanding performance and complete customer satisfaction.

Sai Machine Tools PVT. LTD. has grown to become the largest manufacturing of plastic processing machinery in central India with state of the art screw cutting thread milling less brander(USA) Equipment. The company commenced its operations at plot no. 23, Sector A, Sanwer Road Industrial Area Indore (M.P.) in 1988. Under the technical guidance of Mr. Ashok Jaiswal, who is also the current Managing Director of the company. Under his able leadership, the company had achieved break-even in the very first year of commencement of business. From the very beginning, the strategic focus of the company has been serving international markets. As a result company, today exports 30% of its products. The core focus of the company is innovation carved out of extensive Research and Development efforts carried out by a shear study of needs and the demand of customers of the markets. The company is very quick in expanding the product spectrum as per the needs of the market, as a result, the company now produces both single and twin types of extruders, in such a short duration of time the company has installed more than 1100 extruder's lines globally.

SAI MACHINE TOOLS has moved towards the development of the higher output plant and machinery for HDPE/LDPE and LLDPE pipes and also introduced them to the markets. LDPE/LLDPE 5 Mtr width film and tubing plants having 1000kg /per Hour capacity. The company has also developed a PPR Three-layer pipe plant which is specially used for hot and cold water transportation. The company has installed more than 75 plants successfully with a very high degree of customer satisfaction. The company is fundamentally prepared to meet all the future demands of the industry and market and is in expansion mode. Nowadays SMTPL is concentration on the development of high-speed & precise drip irrigation tube extrusion equipment, with a focus on ease of operation and low maintenance. The company has received an overwhelming response from markets for its indigenously developed drip irrigation tube extrusion equipment.

|

SAI MACHINE TOOLS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese