Gas Nitriding Furnace for Plastic Pipe & Extrusion Component Hardening

Product Details:

- General Use Industrial

- Material Stainless Steel

- Computerized No

- Automatic Yes

- Control System Manual

- Voltage 220-415 Volt (v)

- Color White and Blue

- Click to View more

Gas Nitriding Furnace for Plastic Pipe & Extrusion Component Hardening Price And Quantity

- 1800000.0 INR/Unit

- 1 Unit

Gas Nitriding Furnace for Plastic Pipe & Extrusion Component Hardening Product Specifications

- Manual

- 220-415 Volt (v)

- Industrial

- No

- Yes

- Stainless Steel

- White and Blue

Gas Nitriding Furnace for Plastic Pipe & Extrusion Component Hardening Trade Information

- 30 Days

Product Description

Product DescriptionSai Machine Tools Pvt. Ltd. presents a precision-engineeredGas Nitriding Furnacedesigned specifically for the plastic pipe and extrusion machinery industry. This furnace provides surface hardening of critical components (such as screws, dies, molds, and extrusion barrels) used in the manufacture of plastic pipes, improving their wear resistance, fatigue strength, and operational lifespan.

In plasticpipe extrusion, components like screws and die heads experience intense mechanical stress, abrasion from regrind materials, and thermal cycling. Our gasnitriding furnace helps you enhance component durability, reduce downtime, and maintain consistent product quality.

-

Deep nitrogen diffusion hardening to increase surface hardness and wear resistance.

-

Maintains dimensional tolerances due to low process temperatures (minimal distortion).

-

Improves fatigue strength, corrosion resistance, and tool life in extrusion components.

-

Suitable for extrusion screws, dies, and moldswidely used in plastic molding and extrusion sectors.

-

Fully automated control of temperature and ammonia/nitrogen atmosphere, ensuring a consistent process.

-

Custom sizes are available to match screw length or die tooling configuration.

-

Hardening of extrusion screws used in plastic pipe production (HDPE, PP, PVC, PPR, etc.).

-

Hardening of die heads and mold tooling used in pipe/profile extrusion.

-

Surface-enhancing barrels and other metal components in plastic processing machinery.

-

Improving durability and reducing replacement frequency of wear parts in high-output plastic pipe plants.

-

Supporting longevity of tooling in harsh processing environments (recycled materials, abrasive fillers, etc.).

In the pipe extrusion industry, tool wear and surface degradation of screws and dies can lead to increased downtime, inconsistent pipe dimensions, surface finish defects, and higher maintenance costs. By adopting a gas nitriding furnace, you gain:

-

Longer life of screws/dies fewer tool changes higher uptime.

-

Consistent extrusion quality with smoother surfaces and fewer defects.

-

Lower total cost of ownership of tooling and auxiliary components.

-

Better performance when processing reclaimed/recycled materials (which can be more abrasive).

Having over 37 years of expertise in plastic processing machinery and 3500+ installations worldwide, Sai Machine Tools is a leading Indian manufacturer dedicated to delivering high-performance extrusion solutions. Our commitment to quality, innovation and customer support ensures that you receive machinery built for long-term success.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

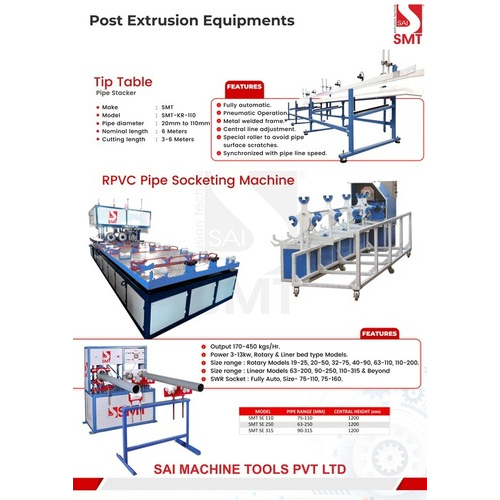

Other Products in 'Post Extrusion Equipments' category

|

SAI MACHINE TOOLS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese