HDPE Pipe Twin Line Extrusion System - HDPE Pipe Plant

Product Details:

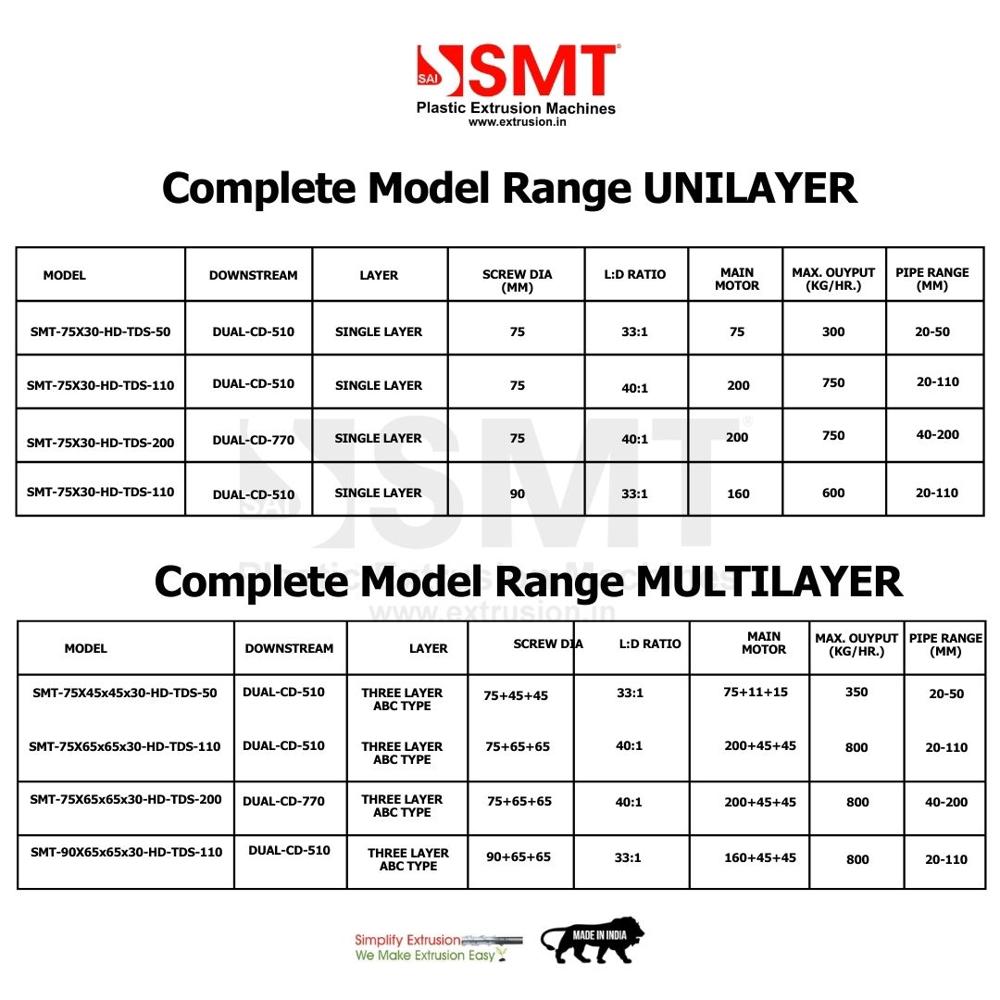

- Motor Power 200 Kilowatt (kW)

- Country Of Origin India

- Usage & Applications Irrigation, Industrial Wastage, Chemical and Water Industry, Telecom Industry

- Speed 20-200 mm/m

- Type HDPE Pipe Extrusion Plant

- Material HDPE

- Computerized Yes

- Click to View more

HDPE Pipe Twin Line Extrusion System - HDPE Pipe Plant Price And Quantity

- 1 Piece

- 20000000.0 INR/Piece

HDPE Pipe Twin Line Extrusion System - HDPE Pipe Plant Product Specifications

- Irrigation, Industrial Wastage, Chemical and Water Industry, Telecom Industry

- Electric

- Human Machine Interface

- HDPE

- Automatic

- Yes

- 200 Watt (w)

- 20-200 mm/m

- Yes

- 300-800 Kg/hr

- Low Manpwer Required, Fully Digital

- 200 Kilowatt (kW)

- Plastic Pipe Extrusion System

- India

- HDPE Pipe Extrusion Plant

- White and Blue

- 200 Kilowatt (kW)

HDPE Pipe Twin Line Extrusion System - HDPE Pipe Plant Trade Information

- 10 Piece Per Month

- 45 Days

Product Description

HDPE Pipe Twin Line Extrusion System | Dual Line HDPE Pipe Plant by Sai Machine Tools

Product Description

Sai Machine Tools Pvt. Ltd. (SMT), one of Indias leading manufacturers of plastic processing machinery, presents its HDPE Pipe Twin Line Extrusion Systema high-performance, fully automated solution designed for maximum productivity and cost efficiency.

Our twin-line extrusion system allows simultaneous production of two HDPE pipes, doubling your output while minimizing space, power, and manpower requirements. Built on German technology and indigenous innovation, this extrusion plant is ideal for HDPE pipe manufacturers looking for efficiency, flexibility, and consistent quality.

The HDPE Twin Line Extrusion System delivers precise weight control, advanced automation, and real-time digital monitoringhelping manufacturers calculate per-kg costing for labor, electrical, and production with ease.

With an efficient layout that requires only 180 feet x 15 feet of space, its a perfect combination of compact design and high throughput.

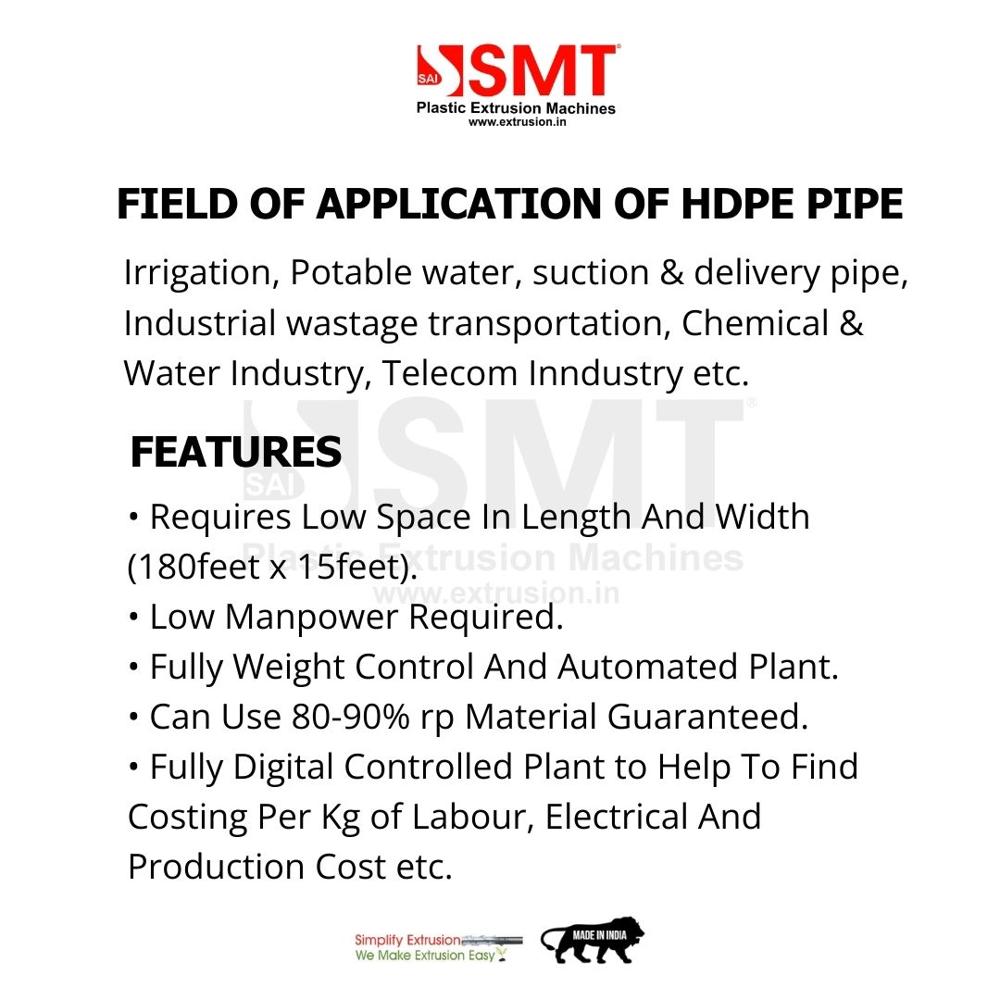

Key Features:

Compact & Space-Saving Design: Requires only 180 ft 15 ft floor space for installation.

Dual Production Line: Capable of extruding two HDPE pipes simultaneouslydouble output with a single setup.

Low Manpower Requirement: The fully automated control system reduces manual intervention and labor costs.

Weight Control System: Advanced digital weight monitoring for consistent pipe wall thickness and accuracy.

High Recycled Material Usage: Compatible with 8090% recycled HDPE raw material without compromising quality.

Smart Cost Analysis: The digital control panel calculates real-time cost per kg for labor, electrical, and production.

Fully Digital & Automated: Intelligent PLC control ensures seamless operation, reduced downtime, and uniform output.

Energy Efficient: Optimized drive system minimizes power consumption while maintaining top performance.

Reliable & Durable: Robust construction ensures long service life, minimal maintenance, and superior productivity.

Applications / Fields of Application:

-

Agricultural Irrigation Lines

-

Potable Water Supply Systems

-

Industrial Waste and Chemical Transport

-

Suction & Delivery Pipes

-

Underground Cable Ducts for Telecom

-

Sewage and Drainage Pipelines

-

Construction and Infrastructure Piping

Packaging Details:

-

Export-quality wooden crate packing with anti-rust protection and moisture sealing.

-

All components are shockproof and safely secured for long-distance transportation.

-

Includes user manual, spare parts kit, and quality inspection report.

-

Customized export packing is available on request.

About Sai Machine Tools Pvt. Ltd. (SMT):

Founded in 1989, Sai Machine Tools Pvt. Ltd. is Indias most trusted manufacturer and exporter of plastic processing machinery, serving over 35+ countries with 3500+ installations worldwide.

SMT is the pioneer in developing innovative extrusion technologies, including the worlds first 3-layer 1200mm diameter extrusion line. With six fully equipped production facilities under one roof, SMT ensures quality control, performance consistency, and complete customer satisfaction.

Our wide range includes PVC/CPVC/UPVC pipe extrusion lines, HDPE pipe plants, PPR/PEX composite systems, drip irrigation lines, and recycling systems.

Why Choose Sai Machine Tools?

Over 37 years of extrusion expertise

Compact, efficient, and high-output designs

Trusted by 1200+ satisfied clients across India and abroad

Strong R&D and award-winning innovation

End-to-end supportfrom installation to training and service

Proven performance in 35+ countries

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

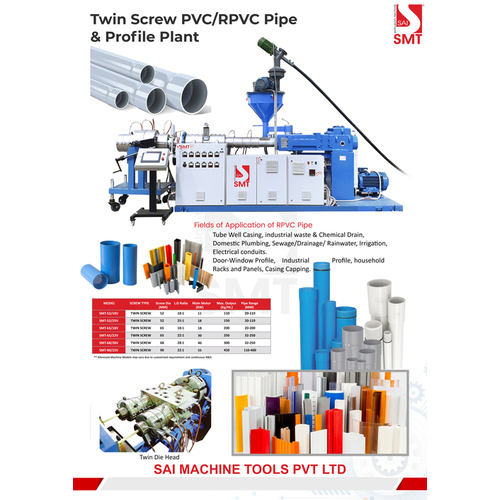

Other Products in 'Twin Screw Extruder' category

|

SAI MACHINE TOOLS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese