Single Screw RPVC Pipe & Profile Plants

6500000.00 - 9000000.00 INR/Unit

Product Details:

- Model No RPVC-S Series

- Plastic Processed RPVC

- Usage & Applications Manufacturing RPVC Pipes & Profiles

- Efficiency (%) >90%

- Speed Up to 60 rpm

- Temperature Range 0C to 250C

- Production Capacity Customized

- Click to View more

X

Single Screw RPVC Pipe & Profile Plants Price And Quantity

- 1 Unit

- 6500000.00 - 9000000.00 INR/Unit

Single Screw RPVC Pipe & Profile Plants Product Specifications

- Customized

- 30-110 kW

- Rigid Polyvinyl Chloride (RPVC)

- 6000 - 9800 kg

- >90%

- Blue & White

- Up to 60 rpm

- 0C to 250C

- Manufacturing RPVC Pipes & Profiles

- 380V / 415V

- RPVC

- 20000 x 2500 x 2500 mm (approx)

- Automatic

- RPVC-S Series

- Powder Coated

- Single Screw RPVC Pipe & Profile Plant

- 110 - 450 kg/hr

- As per machine configuration

- PLC Control

- Yes

- Electric

- Automatic

- Single Screw Extruder

- Pipe & Profile Extrusion Plant

- On-site training & manual provided

- 50 Hz

- Die head, Cooling Tank, Haul-off Unit, Cutter, Stacker

- High Output, Uniform Plasticizing, Stable Operation

- 30 - 110 kW

Single Screw RPVC Pipe & Profile Plants Trade Information

- 1 Unit Per Week

- 1 Months

Product Description

The offered Single Screw RPVC Pipe & Profile Plants is made available by us for use in various commercial and industrial applications. Single screw plants have more widely usage for general plastic material and recycled plastic material extrusion which doesnt care about the compounding ability. Due to the advantage of less heat of friction, more uniform shearing, larger conveying capacity of screw, more stable extrusion, twin screw extruder more suitable for plastic material compounding and modification. They are very useful and made

Specification

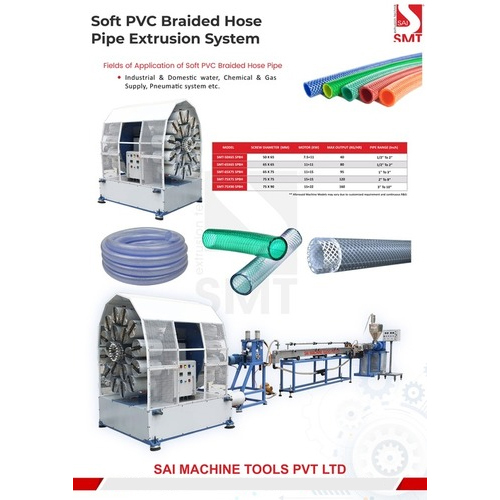

| Model | Screw Diameter (mm) | LD Ratio | Motor (Kw) | Max. output (kg/hr) | Pipe range (mm) |

| SMT 65 RPVC | 65 | 24:1 | 11 | 50 | 16-75 |

| SMT 75 RPVC | 75 | 24:1 | 15 | 80 | 16-110 |

| SMT 90 RPVC | 90 | 24:1 | 30 | 100 | 20-160 |

Advanced Extrusion Technology

The RPVC-S Series is equipped with a high-performance single screw extruder, precise barrel heating (four controlled zones), and a robust alloy steel die head. This configuration ensures uniform plasticizing and stable operation, delivering consistent pipe and profile quality across varying diameters and wall thicknesses.

Automated and Safe Operation

The plant features a fully automatic grade with PLC-based controls, centralized automatic lubrication, and a cutting-edge automatic inline cutter. Integrated safety systems, including overload protection, emergency stops, and interlocks, safeguard both users and machinery during continuous operation.

Flexibility and High Capacity

Designed for versatility, the machine handles input materials in granule or pellet form and offers production customization up to 450 kg/hr. Pipe diameter capacity ranges from 16 mm to 160 mm, making it suitable for diverse manufacturing requirements. The process operates efficiently at speeds up to 60 rpm and above 90% efficiency.

FAQs of Single Screw RPVC Pipe & Profile Plants:

Q: How does the single screw extruder enhance RPVC pipe and profile production?

A: The single screw extruder offers uniform plasticizing and stable operation by maintaining precise temperature control across four heating zones. This design achieves high output rates, superior product consistency, and smooth material flow, optimizing the extrusion of RPVC pipes and profiles.Q: What types of pipes and profiles can be manufactured with this plant?

A: This plant is designed to manufacture rigid polyvinyl chloride (RPVC) pipes and profiles, covering diameters from 16 mm to 160 mm. It is suitable for producing various profiles and customized pipe dimensions based on the application requirements.Q: When should maintenance be performed on the plant?

A: Routine maintenance is simplified thanks to the plants centralized automatic lubrication system. However, periodic checks according to the manufacturers manual, especially before starting a new production cycle or after extensive use, are recommended to ensure long-term performance and minimal downtime.Q: Where is the optimal installation environment for this extrusion plant?

A: The plant should be installed in an industrial environment where ambient temperatures do not exceed 45C. Adequate space is necessary to accommodate the machine dimensions, and proper ventilation ensures effective operation of the cooling and air blower systems.Q: What is the process flow for pipe and profile production?

A: RPVC granules or pellets are fed into the extruder, where they are melted and forced through the die head. The extruded material is shaped, cooled via water and air, and continuously moved by the haul-off unit. An automatic inline cutter trims the products to length before stacking.Q: How does the plant benefit users in terms of safety and efficiency?

A: The plant incorporates advanced safety features such as emergency stops, interlocks, and overload protection. Its automatic, PLC-controlled operation with low noise and high efficiency ensures a safe working environment and consistent, high-quality production output.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Single Screw Extruder' category

|

SAI MACHINE TOOLS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese