Flat Drip Irrigation Tube Extrusion System High Speed Drip Pipe Making Machine

Product Details:

- Frequency 500 Hertz (HZ)

- Motor Power 150 Volt-Ampere (VA)

- Speed 220 m/m

- Country Of Origin India

- Production Capacity 220 Pcs/min

- Usage & Applications Manufacturing of Flat Drip Irrigation Pipes, Suitable for agriculture & irrigation industries, Ideal for water-saving irrigation projects.

- Type HDPE PIPE PLANT

- Click to View more

Flat Drip Irrigation Tube Extrusion System High Speed Drip Pipe Making Machine Price And Quantity

- 12700000.0 INR/Unit

- 1 Unit

Flat Drip Irrigation Tube Extrusion System High Speed Drip Pipe Making Machine Product Specifications

- 220 Pcs/min

- Yes

- White an blue

- Electric

- Automatic

- Manufacturing of Flat Drip Irrigation Pipes, Suitable for agriculture & irrigation industries, Ideal for water-saving irrigation projects.

- PLC Control

- 1 year

- 40 to 422 HP Horsepower (HP)

- 500 Hertz (HZ)

- High Speed & Productivity, Line speed up to 220 meters per minute, Insertion & perforation capacity of 700 drippers per minute, Supports dripper spacing from 200 mm to 2000 mm

- HDPE PIPE PLANT

- 150 Volt-Ampere (VA)

- 220 m/m

- HDPE

- India

Flat Drip Irrigation Tube Extrusion System High Speed Drip Pipe Making Machine Trade Information

- Cash Against Delivery (CAD)

- 10 Unit Per Month

- 1 Week

- No

- Packaging Details 1. Machine packed with protective wrapping (bubble sheet & stretch film) to avoid scratches and dust during transit. 2. Critical components (die head, electrical panels, control units) packed in wooden crates for extra safety. 3. Entire extrusion line loaded on wooden pallets / steel skids with proper strapping. 4, Export shipments are sea-worthy and containerized with fumigation-treated wooden packing (as per international standards). 5. Clear marking & labeling for easy identification during unloading and installation.

- Asia, North America, Middle East, Africa

- All India

Product Description

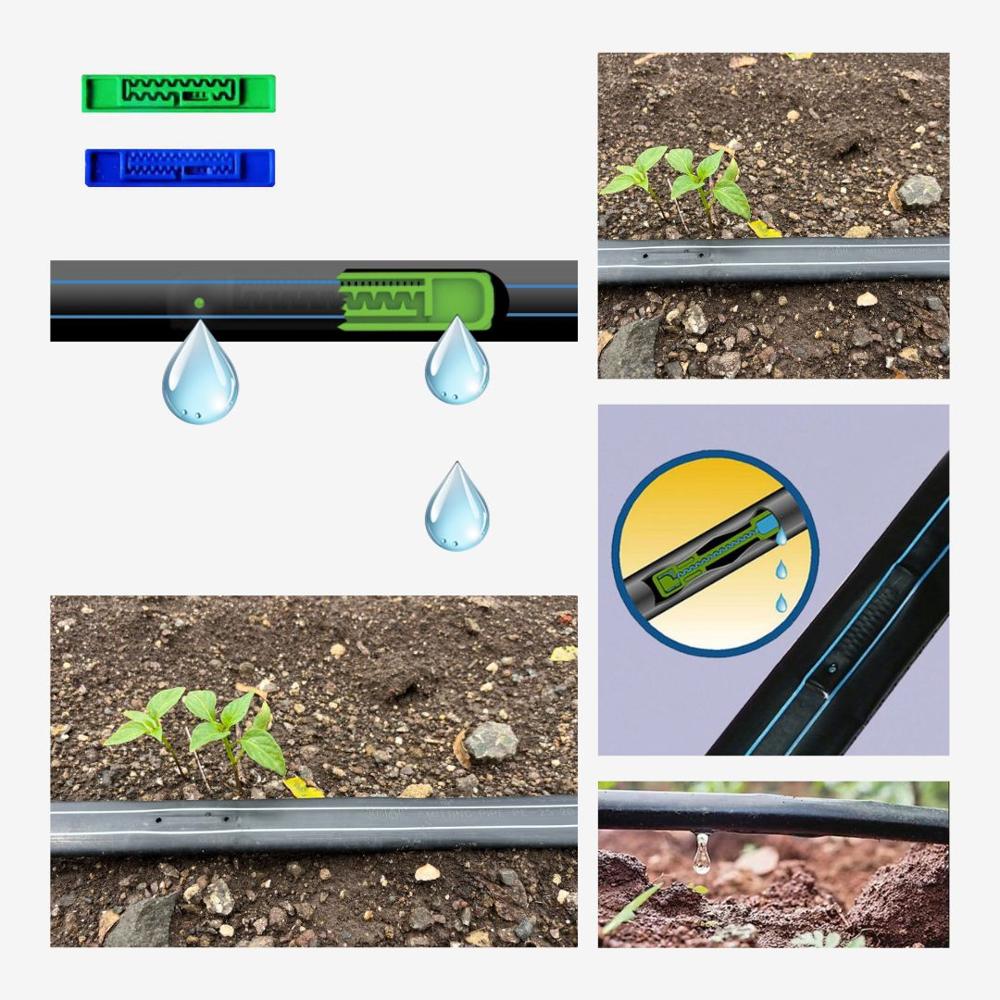

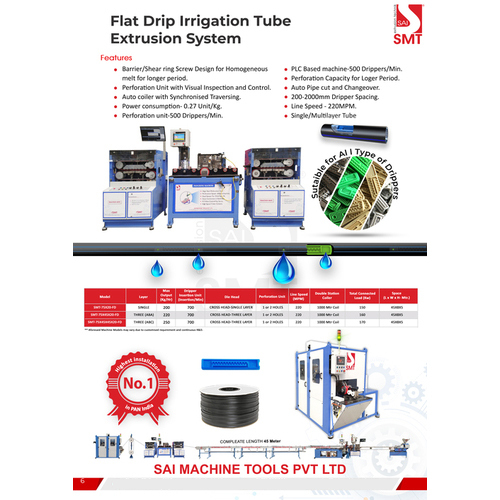

Flat Drip Irrigation Tube Extrusion System

Product Overview

Sai Machine Tools (SMT), Indias leading manufacturer of plastic processing machinery, introduces its Flat Drip Irrigation Tube Extrusion System, a high-performance, energy-efficient, and fully automated solution for modern irrigation pipe production. This system is designed to meet the growing demand for precision irrigation technology while ensuring cost efficiency, durability, and maximum productivity.

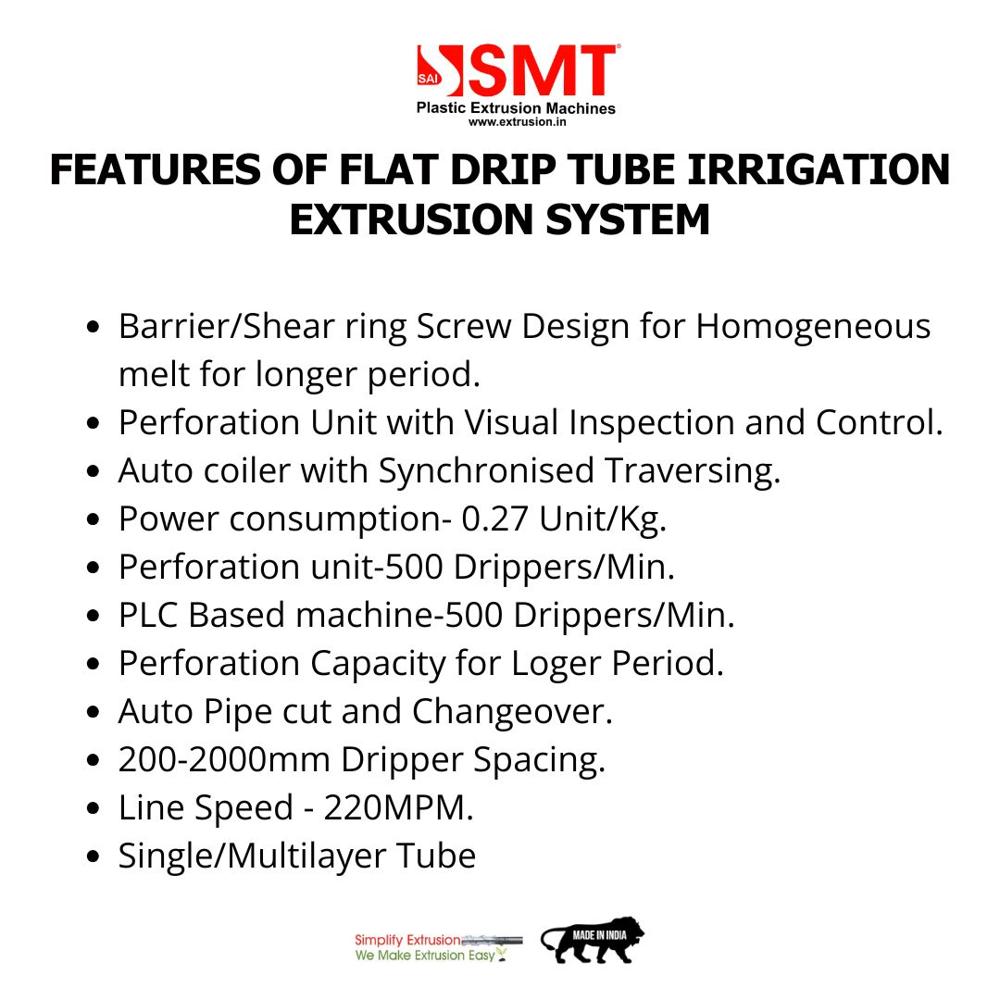

Key Features & Advantages

High Speed & Productivity

-

Line speed up to 220 meters per minute

-

Insertion & perforation capacity of 700 drippers per minute

-

Supports dripper spacing from 200 mm to 2000 mm

Advanced Automation

-

PLC-based intelligent control system for synchronized operation

-

Auto coiler with traversing for neat winding

-

Auto cutting & pipe changeover system ensures uninterrupted production

Energy Efficiency

-

Low power consumption: only 0.27 units per kg of production

-

Optimized screw & barrel design with barrier/shear ring screw for better mixing and homogeneous melting

Versatile Design

-

Capable of producing single-layer or multi-layer drip irrigation tubes

-

Equipped with high-precision die head and perforation unit with visual inspection system

-

Uniform dripper insertion for reliable field performance

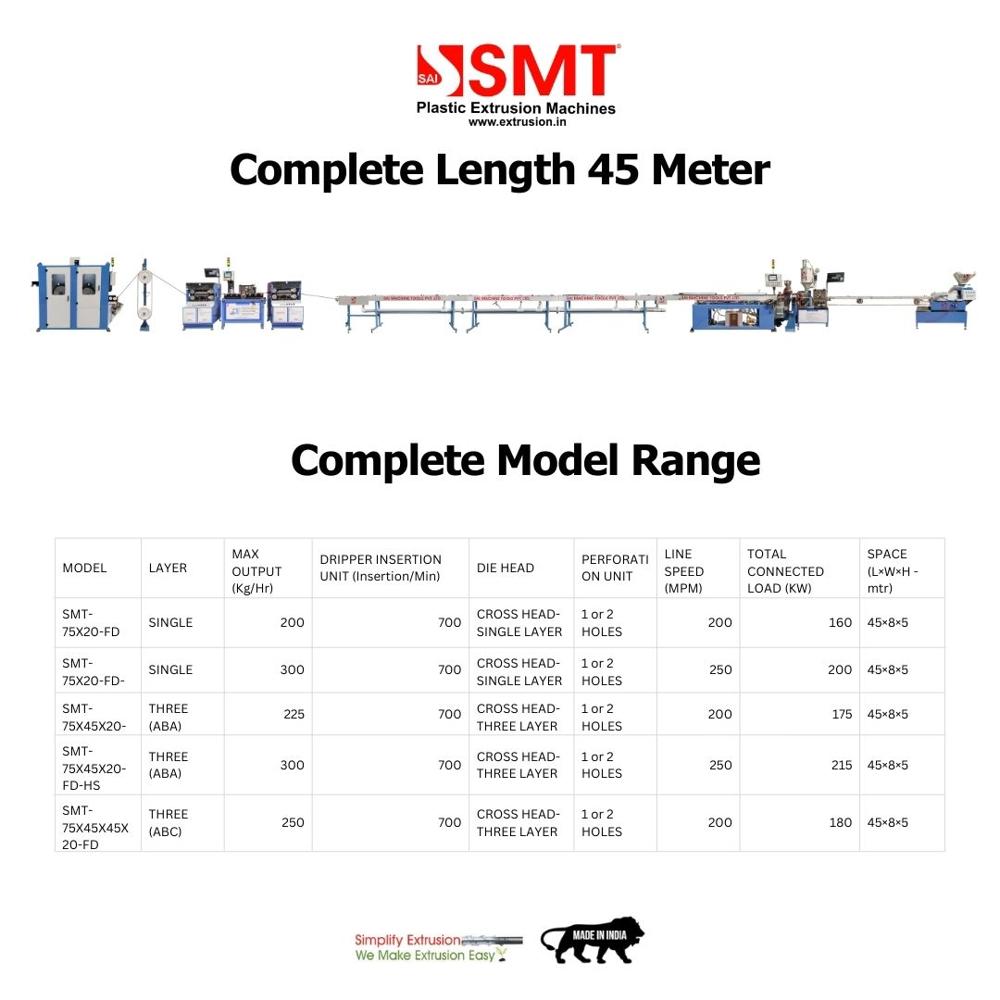

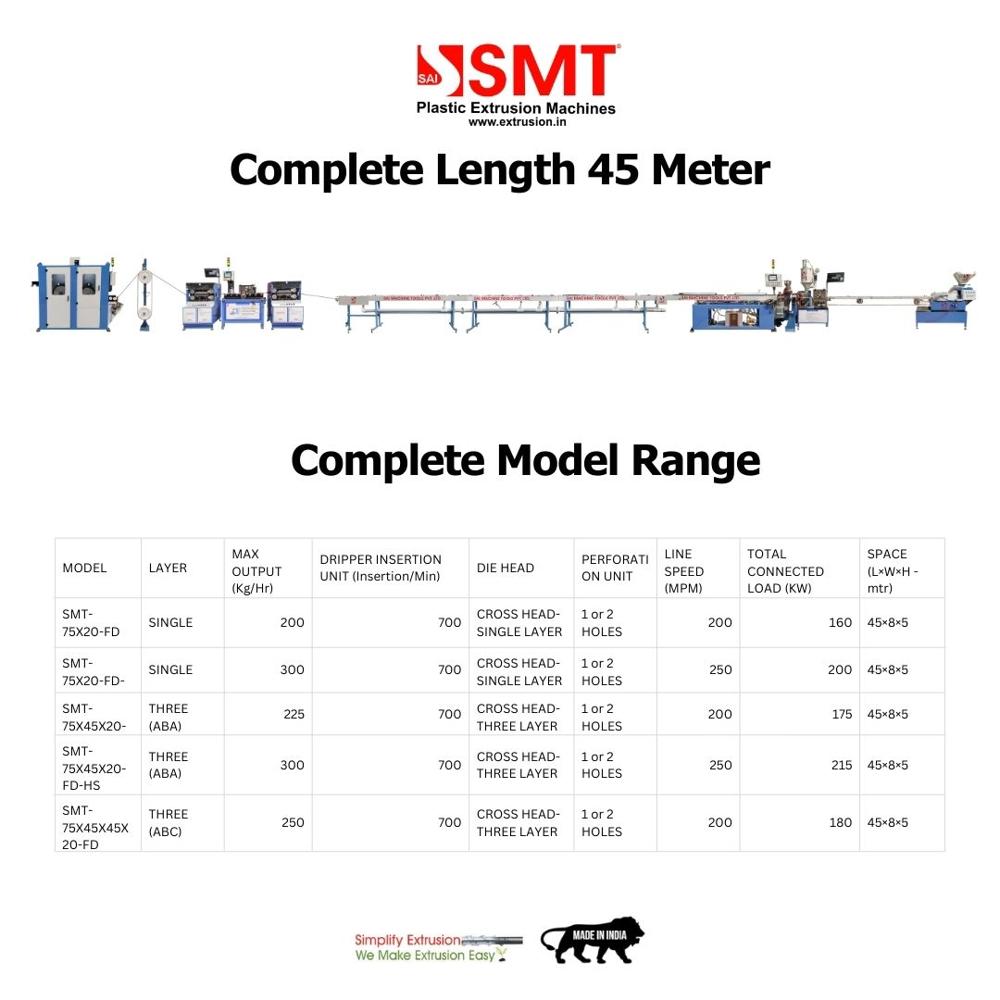

Technical Specifications

-

Production Speed: Up to 220 MPM

-

Dripper Insertion: 700 drippers/min

-

Perforation Unit: Up to 500 drippers/min, with visual inspection

-

Dripper Spacing: 200 mm 2000 mm

-

Layer Options: Single / Multi-layer (ABC / ABA)

-

Connected Load: Energy-efficient configuration with low kW consumption

-

Space Requirement: Compact footprint for easy installation

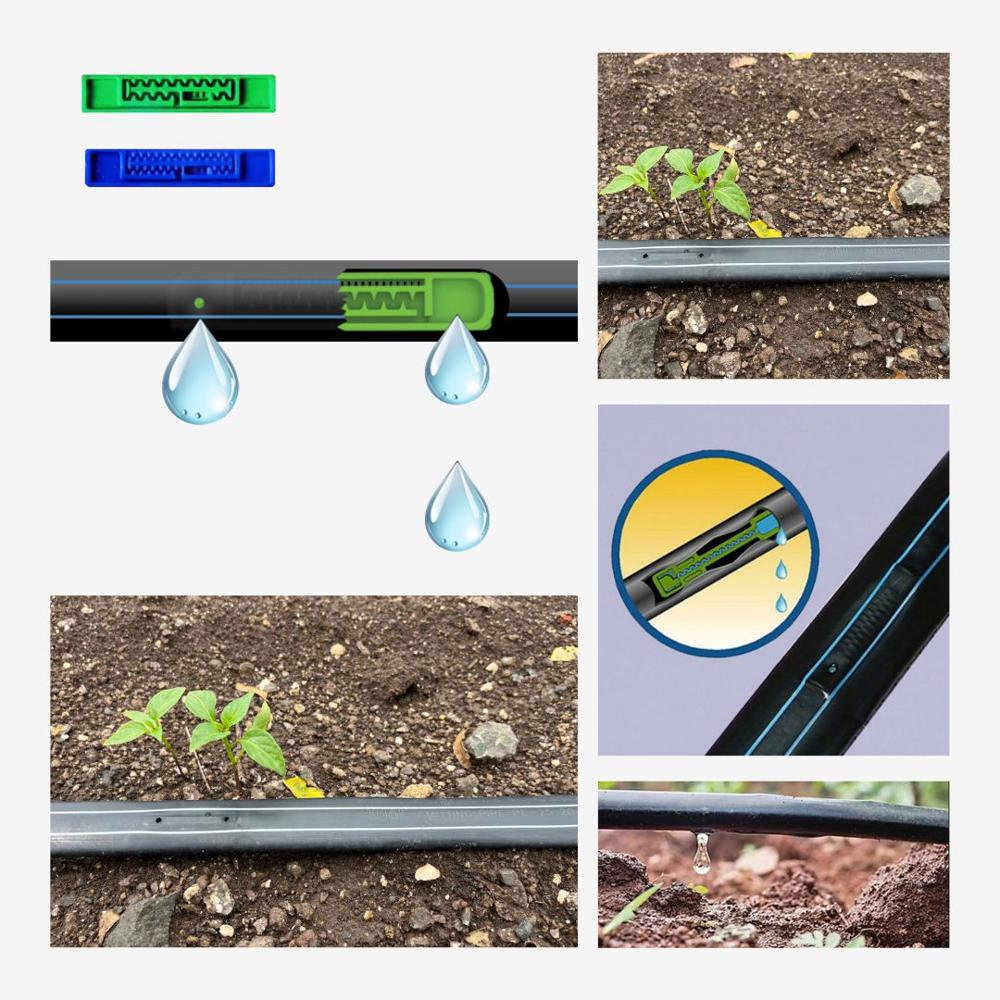

Applications

Manufacturing of Flat Drip Irrigation Pipes

Suitable for agriculture & irrigation industries

Ideal for water-saving irrigation projects

Widely used by pipe manufacturers and OEMs

Why Choose SMT?

-

Global Presence 3200+ extrusion lines installed worldwide

-

Award-Winning Innovation National Award for Research & Development and Outstanding Entrepreneurship (MSME)

-

Complete In-House Manufacturing 6 state-of-the-art production facilities

-

Proven Expertise 36+ years of leadership in extrusion technology

-

Trusted by 1200+ customers across 35+ countries

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Inline Dripper Irrigation Tube Extrusion Line' category

|

SAI MACHINE TOOLS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese