HDPE Pipe Extrusion System | Unilayer & Multilayer Series | Extrusion Lines by Sai Machine Tools Pvt. Ltd.

Product Details:

- Production Capacity 16 Ton

- Country Of Origin India

- Usage & Applications Water Supply & Distribution Networks, Sewage and Drainage Systems, Irrigation & Agricultural Applications , Cable Ducts & Conduits Gas Distribution Pipelines, Industrial Fluid Transport Lines

- Type HDPE PIPE PLANT

- Material HDPE, MDPE, LLDPE, LDPE

- Computerized Yes

- Automatic Grade Automatic

- Click to View more

HDPE Pipe Extrusion System | Unilayer & Multilayer Series | Extrusion Lines by Sai Machine Tools Pvt. Ltd. Price And Quantity

- 33000000.0 INR/Piece

- 1 Kilograms

HDPE Pipe Extrusion System | Unilayer & Multilayer Series | Extrusion Lines by Sai Machine Tools Pvt. Ltd. Product Specifications

- HDPE PIPE PLANT

- HDPE, MDPE, LLDPE, LDPE

- 16 Ton

- Yes

- India

- PLC Control

- Water Supply & Distribution Networks, Sewage and Drainage Systems, Irrigation & Agricultural Applications , Cable Ducts & Conduits Gas Distribution Pipelines, Industrial Fluid Transport Lines

- Fully Automatic (Digitally Controlled)

- 40 to 422 HP Horsepower (HP)

- High Output Capacity, Low Power Consumption, Advanced Automation, Customizable Configuration, Complete Turnkey Solution.

- whitew and blue

- Electric

- 45 Volt (v)

- Automatic

- 16 Ton

- 0.25 0.27 units/kg Kilowatt (kW)

- 1 year

HDPE Pipe Extrusion System | Unilayer & Multilayer Series | Extrusion Lines by Sai Machine Tools Pvt. Ltd. Trade Information

- Cash Against Delivery (CAD), Cash Advance (CA), Cheque, Delivery Point (DP), Letter of Credit (L/C)

- 1 Kilograms Per Week

- 1 Week

- No

- Free samples available with shipping and taxes paid by the buyer

- 1. Packaging Type: Heavy-duty stretch film wrapping / plastic film wrapping with moisture protection; Wooden box/crates used for delicate and precision components 2. Delivery Condition: Machine securely mounted on MS base frame / wooden pallets to prevent movement during transit 3. Accessories & Tools: Supplied in separate, labeled cartons for easy identification 4. Electrical Control Panel & Coiling Unit: Individually wrapped, cushioned, and packed to ensure protection from dust and vibrations 5. Export Protection: Anti-rust coating and moisture barrier applied where required for overseas shipment 6. Suitable For: Both domestic and international transportation by road, sea, or air

- Asia, Central America, Middle East, Africa

- All India

- Certified by IAF & IAS; ISO quality management; winners of national awards in R&D & plastic machinery excellence; complying with international standards.

Product Description

Product Description

Sai Machine Tools Pvt. Ltd. (SMT) proudly introduces its All-Rounder Series of HDPE Pipe Extrusion Systems, designed for high-speed, precision, and energy-efficient production of HDPE, MDPE, LLDPE, and LDPE pipes.

Available in both Unilayer and Multilayer configurations, these extrusion systems are built for seamless pipe manufacturing ranging from 16 mm to 1200 mm in diameter, catering to diverse industrial, irrigation, and infrastructure applications.

SMT's HDPE extrusion lines are engineered with advanced automation, digital process control, and high-capacity extruders, ensuring maximum productivity, consistent wall thickness, and low operational costs. Each system is offered with complete tooling for PN and SDR classes, complying with international pipe manufacturing standards.

Key Features of HDPE Pipe Extrusion System

- High Output Capacity Supports production up to 1619 tonnes per day for pipe sizes 63 mm to 110 mm.

- Low Power Consumption: Only 0.25 to 0.27 units per KG, ensuring energy efficiency.

- Compact Footprint Requires minimal floor space (180 ft x 15 ft) for installation.

- Advanced Automation Fully weight-controlled and digitally monitored production system.

- Recycling Compatibility Capable of processing 80-90% reprocessed (RP) material without quality compromise.

- Low Manpower Operation Designed for easy handling and reduced labor dependency.

- The Cost Monitoring System digitally tracks labor, electrical, and production costs per kilogram.

- Customizable Configuration Available in unilayer and multilayer variants for different applications.

- Complete Turnkey Solution Includes die head, cooling tank, haul-off, cutter, and coiler units.

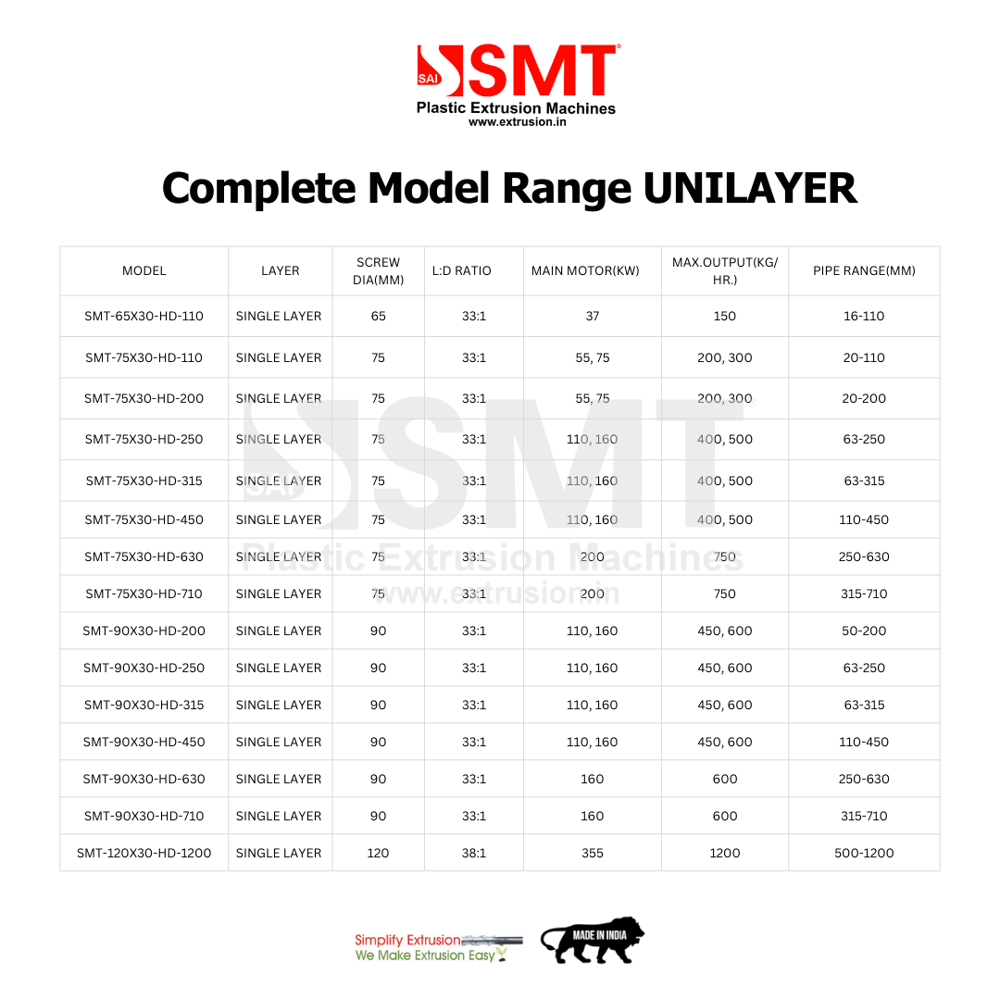

HDPE Unilayer Pipe Extrusion System

The Unilayer HDPE Extrusion System is designed for cost-effective, single-layer pipe production with high uniformity and consistent wall thickness. It is ideal for producing pipes for water supply, gas distribution, and cable ducting applications.

Key Highlights:

-

Space requirement: 180 ft 15 ft

-

Output: 1619 tonnes per day (for 63110mm dia coils)

-

Power Consumption: 0.250.27 units per KG

-

RP Material Usage: Up to 90% reprocessed plastic

-

Fully automated, digitally controlled operation

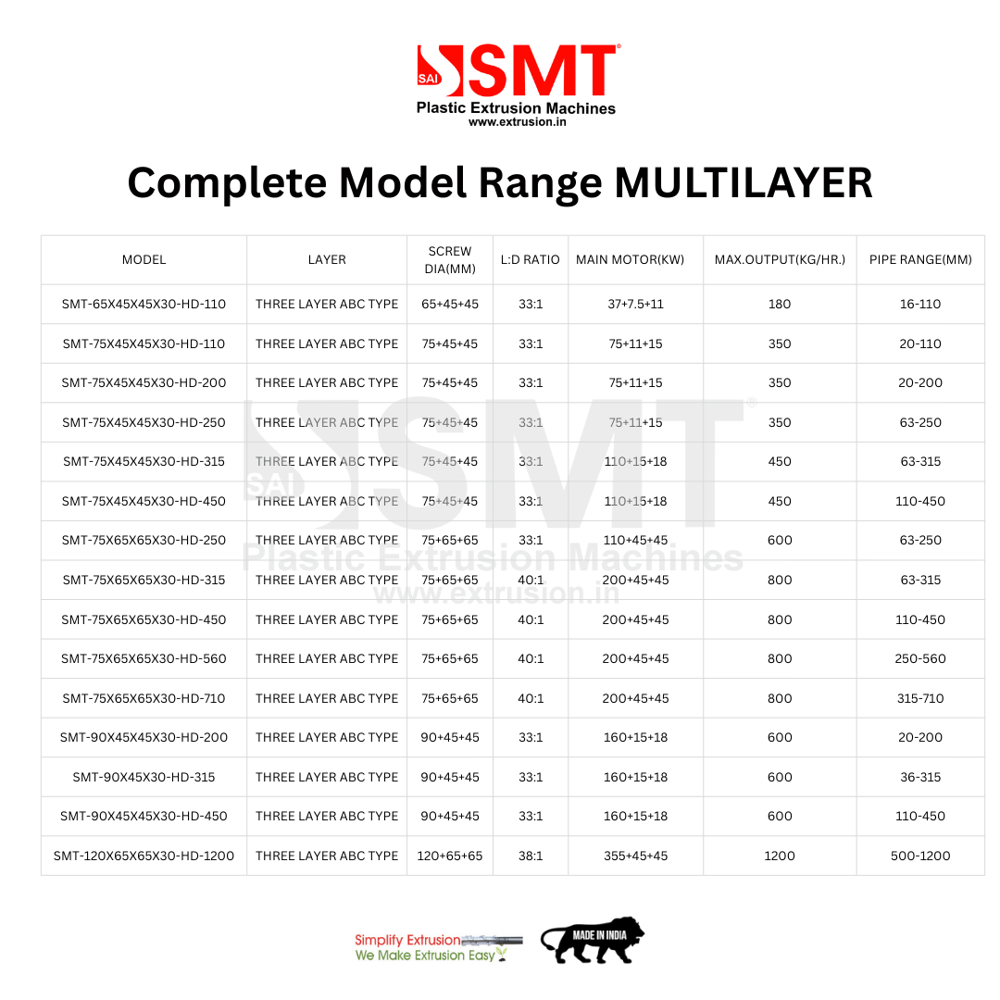

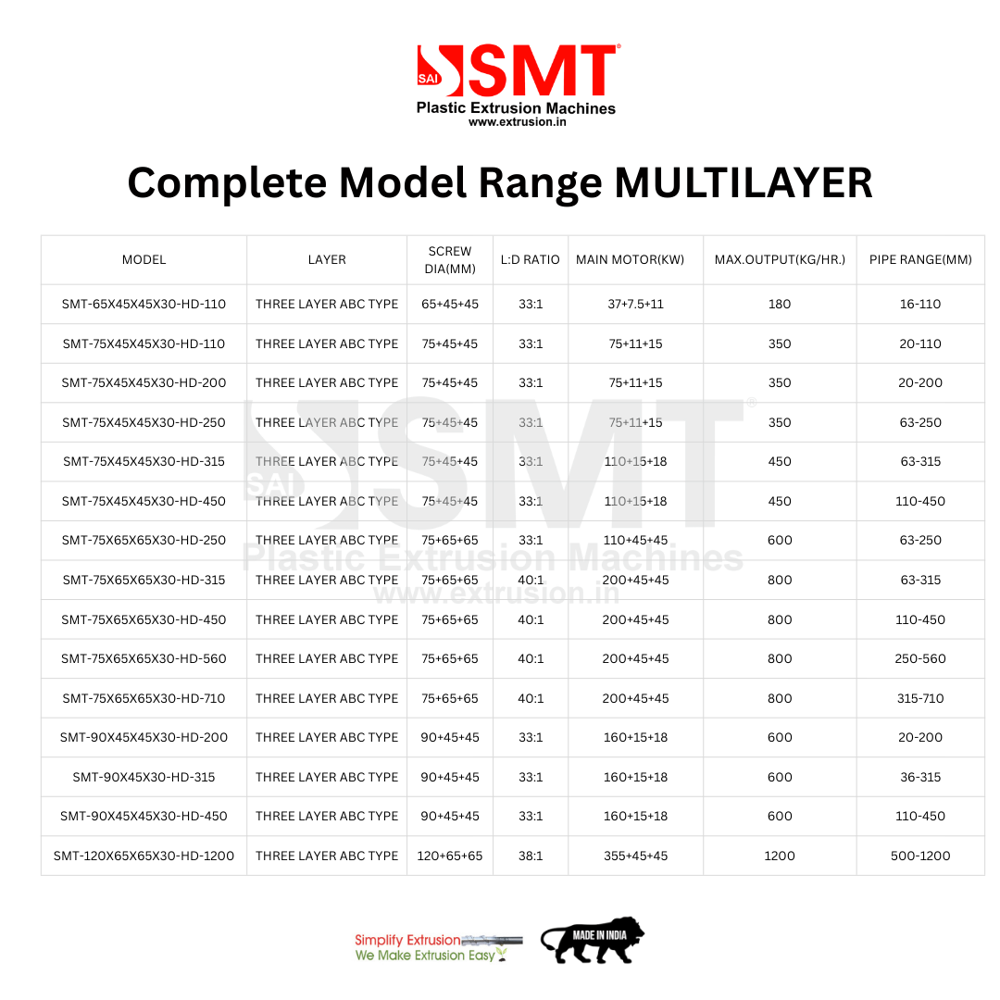

HDPE Multilayer Pipe Extrusion System

The Multilayer HDPE Pipe Extrusion System offers enhanced strength, flexibility, and material optimization by combining different polymer layers. Ideal for pressure pipes, sewage systems, irrigation, and industrial conduits, this system ensures superior performance and durability.

Advantages:

-

Multiple layers for improved mechanical strength and chemical resistance

-

Suitable for HDPE, MDPE, and LLDPE combinations

-

Optimized wall structure reduces raw material consumption

-

Ensures smooth inner surface for better flow efficiency

-

Compatible with co-extrusion die heads and gravimetric systems

Applications

-

Water Supply & Distribution Networks

-

Sewage and Drainage Systems

-

Irrigation & Agricultural Applications

-

Cable Ducts & Conduits

-

Gas Distribution Pipelines

-

Industrial Fluid Transport Lines

Product Specifications

|

Specification |

Details |

|

Brand |

Sai Machine Tools Pvt. Ltd. |

|

Series Name |

All-Rounder HDPE Pipe Extrusion System |

|

Machine Types |

Unilayer / Multilayer |

|

Pipe Range |

16 mm to 1200mm |

|

Materials Processed |

HDPE, MDPE, LLDPE, LDPE |

|

Production Capacity |

1619 tonnes/day (for 63110mm dia) |

|

Space Requirement |

180 ft 15 ft |

|

Electrical Consumption |

0.250.27 units/kg |

|

Reprocessed Material Usage |

Up to 90% RP |

|

Automation Type |

Fully Automatic (Digitally Controlled) |

|

Tooling Range |

PN & SDR Class Pipes |

|

Country of Origin |

Made in India |

|

Warranty |

1 Year (Manufacturing Defects) |

About Sai Machine Tools Pvt. Ltd.

Established in 1988, Sai Machine Tools Pvt. Ltd. (SMT) is a leading global manufacturer and exporter of plastic processing machinery with 35+ years of experience and 3200+ installations across 35+ countries.

SMT specializes in pipe extrusion lines, recycling systems, pelletizers, pulverizers, and drip irrigation machinery.

Recognized with National Awards for R&D and Outstanding Entrepreneurship by the President of India, SMT is committed to

delivering world-class technology, performance, and reliability.

Why Choose Sai Machine Tools?

Global Presence Trusted by 1200+ customers worldwide.

Turnkey Solutions From raw material feeding to finished coiling.

In-House Manufacturing All components are produced under one roof.

Award-Winning R&D Recognized for innovation and technological excellence.

Expert Engineering Team: Decades of extrusion design experience.

High ROI Machines Low energy cost, high production efficiency.

Strong After-Sales Service Installation, training, and technical support.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Single Screw Extruder' category

|

SAI MACHINE TOOLS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese